1000 (brand) series aluminum alloy represents 1050, 1060, 1100. In all series, 1000 series belongs to the most aluminum series, purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively single, and its price is relatively cheap. It is currently one of the most commonly used series in the conventional industry. Most of the current circulation on the market is 1050 and 1060 series, 1000 series aluminum plate determine the minimum aluminum content of this series according to the last two Arabic numerals. Its characteristics are: good electrical conductivity, good corrosion resistance, good welding performance, low strength. In terms of use, it is relatively soft, mainly used to do decorative parts or interior parts, mostly used in the chemical industry and special purposes.

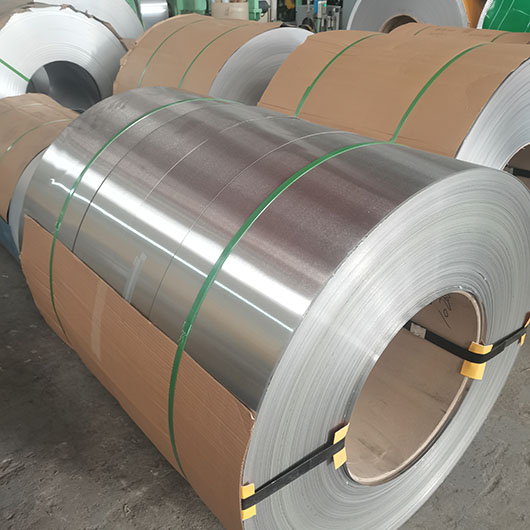

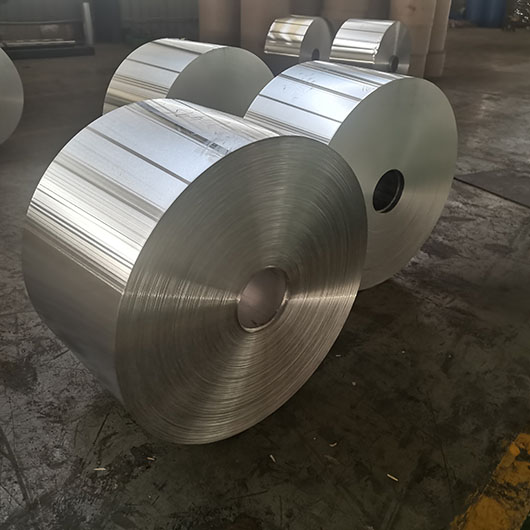

Aluminum coil is a metal product of rolling and rolling corners. It is widely used in electronics, packaging, construction, machinery and other aspects. Most of the aluminum coils produced by our company are between 0.5 mm and 4 mm thick, and the width is generally from 500 mm to 2200 mm.

1 Series Aluminum Coil Parameter:

| Alloy | 1050/1060/1100 |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38/H114 H321/H116 |

| Thickness | 0.5-4.0mm 4.1-10.0mm |

| Width | 500-2200mm |

| Surface | Mill Finish |

| Type | Cold rolled(CC)/Hot rolled(DC) |

1 Series Aluminum Coil Application:

Cookware: processing methods include polishing, sand-blasting, etc. Used for base cover of AL pot cover, AL kettle, and electromagnetic cooker, etc.

Lamp accessories: lamp cover, lamp cup, etc.

Indicative signs and building materials: traffic signs, building decorative materials, etc.

3 series aluminum alloy is also known as aluminum manganese alloy, widely used as antirust aluminium alloy series. The strength of the 3 series aluminum alloy is high pure aluminum alloy. After cold work and annealing process, it has good plasticity, corrosion resistance and welding performance. It can be used in many industries, such as building decoration industry, electronic industry, automobile manufacturing and so on. We are aluminum products supplier and manufacturer, and have our advanced production lines and mature marketing system. We mainly concentrate on aluminum sheet/plate, aluminum circle/disc and aluminum coil, with the main brand 3003, 3004 , 3005, 3104 , 3005 , 3105 for your reference.

3 series aluminum coil also known as heat treatment non-strengthening alloy with high plasticity, good welding performance. We can supply excellent aluminum coils with thicknesses between 0.5mm-4mm, 4.1-10.0mm and width ranging between 500-2200mm. It is mainly used in the manufacturing of automobile, aircraft fuel tank oil pipe, container tank, mechanical parts and other fields.

3003 aluminum coil has good anti-rust performance, excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is suitable for pipeline and tank anti-corrosion heat preservation, kitchenware, food and chemical products processing and storage devices, plate processing of various pressure vessels and pipes.

3004 aluminum coil is the best aluminum material in the three series. It is an alloy series aluminum coil. 3004 aluminum coil is higher than 3003 in hardness and price aspects, and the elongation is also higher than 3003. It commonly used in metal roof, metal plate strength, cans and other products.

3104 aluminum coil is a deformed aluminum alloy, tensile strength is greater than or equal to 275MPA and elongation can reach 20%. With good deep punching performance, it is suitable for pull-ring material, lamp cap material, shutter material, oxidizing material, color coated aluminum plate base and automobile fuel tank.

3 Series Aluminum Coil Parameter:

| Alloy | 3003/3004/3005/3104/3105 |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38/H114 H321/H116 |

| Thickness | 0.5-10.0mm |

| Width | 500-2200mm |

| Surface | Mill Finish |

| Type | Cold rolled(CC)/Hot rolled(DC) |

Its common types include 5005, 5052, 5083, 5754, etc.

5000 series aluminum alloy, also known as Al-Mg alloy, is mixed with magnesium. Characterized by low density, high tensile strength, high elongation and excellent corrosion resistance, it’s weldable and applied to a wide variety of purposes including pressure vessels, automotive, buildings, etc., especially suitable for marine environment.

5 Series Aluminum Coil Parameter:

| Alloy | 5005/5052/5754/ 5083 |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38/H114 H321/H116 |

| Thickness | 0.5-4.0mm 4.1-10.0mm |

| Width | 500-2200mm |

| Surface | Mill Finish |

| Type | Cold rolled(CC)/Hot rolled(DC) |

5 Series Aluminum Coil Application

5005: Storage tanks, chemical equipment, food processing equipment, roofing & siding materials, etc.

5052: Pressure vessels, treadplate, marine components, chemical equipment, road & name signs, etc.

5754: Ship building, food processing equipment, treadplate, vehicle bodies, fish industry equipment, welded chemical & nuclear structures, etc.

5083: Rail cars, pressure vessels, vehicle bodies, ship building, mine cages & skips, tipper truck bodies, etc.

The 6000 series aluminum alloy mainly contains two elements, magnesium and silicon, so it concentrates the advantages of the 4000 series and the 5000 series, and is a cold-treated aluminum forging product. Suitable for applications requiring high resistance to corrosion and oxidation. Good usability, excellent interface characteristics, easy coating, and good workability.

Features: Mainly contains magnesium and silicon. Mg2Si is the main strengthening phase and is currently the most widely used alloy. 6063, 6061 are used most, other 6082, 6160, 6125, 6262, 6060, 6005, 6463. 6063, 6060, and 6463 have relatively low strength in the 6 series. 6262, 6005, 6082, and 6061 have relatively high strength in the 6 series.

Medium strength, good corrosion resistance, good welding performance, good process performance (easy to extrude and form), good oxidation and coloring performance.

Application range:

energy transfer tools,

car luggage racks,

doors,

windows,

body,

heat sinks,

inter-box shells.

6 Series Aluminum Coil Parameter:

| Alloy | 6061/6082 |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38/H114 H321/H116 |

| Thickness | 0.5-4.0mm 4.1-10.0mm |

| Width | 500-2200mm |

| Surface | Mill Finish |

| Type | Cold rolled(CC)/Hot rolled(DC) |

6 Series Aluminum Application:

6082 aluminum alloy is a medium strength alloy with excellent corrosion resistance. 6082 aluminum alloy has the highest strength of the 6000 series alloy. Due to the higher strength of 6082 aluminum alloy it has replaced Alloy 6061 in many applications.

6082 aluminum alloy is typically used in highly stressed applications, Trusses, Bridges, Cranes, Transport applications, Ore Skips, Beer Barrels, Milk churns.

The 8000 series includes 8011, 8090, 8091 and 8093. Lithium has a significantly lower density than aluminum because its solubility is also relatively high, and it can significantly reduce the density in a sufficient amount of aluminum alloys (usually about 10%, less than other aluminum alloys). Not only causes the alloy to increase its stiffness, but also responds to age hardening. In addition, the resistance to fatigue crack growth increases at intermediate pressure levels. This attractive combination of properties has led to great interest, especially for aerospace applications. These alloys have a high volume fraction of coherent, ordered LiAl 3 precipitation, which is responsible for these properties. Silicon strength: For example, the 8011 alloy is based on Al-Fe-Si, but more than 1% of the total alloying elements give a correspondingly higher advantage.

The 8000 series are alloyed with a variety of other elements such as iron and lithium. Generally, they are created for very specific purposes within specialist industries such as aerospace and engineering. They offer similar properties to the 1000 series but with higher strength and formability.

Characteristic:

Belongs to aluminium-lithium alloy, the main component is lithium, cause lithium is the lightest metal in nature, after adding lithium element to aluminum plate, it can guarantee the strength of aluminum plate while effectively reducing the proportion of aluminum plate.

8011 Aluminum Alloy Coil:

8011 aluminium alloy is a common aluminum foil alloy with iron and silicon as the main alloying elements. It has been widely used in sealing packing of cosmetic bottles, beverage bottles and air conditioning aluminum foil because of its good deep drawing performance and low earing rate.

8 Series Aluminum Coil Parameter:

| Alloy | 8011 |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38/H114 H321/H116 |

| Thickness | 0.5-4.0mm 4.1-10.0mm |

| Width | 500-2200mm |

| Surface | Mill Finish |

| Type | Cold rolled(CC)/Hot rolled(DC) |

1050 aluminium coil is an aluminium-based alloy in the “commercially pure” wrought family (1000 or 1xxx series). It has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. It has low mechanical strength compared to more significantly alloyed metals. It can be strengthened by cold working, but not by heat treatment. The production process is relatively simple and the price is relatively cheap. It is the most commonly used series in the conventional industry.

Chemical Composition of The 1050 Aluminium Coil:

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | 0.07 | 0.05 | 0.15 | Remain |

Specifications of The 1050 Aluminium Coil:

| Temper | F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114 |

| Thickness (mm) | 0.1-8 |

| Width (mm) | 40-2650 |

| Length (mm) | Customized |

| Typical applications | Battery soft connections, Chemical industry containers, PS plate base, CTP plate, Signage, Pallet, Lamps, Heat sink, etc. |

Advantages of The Aluminum Coil

High strength

Resistant high mechanical stresses

Resistant to high temperature

Good formality

Long life, lower cost, but also has a high recovery value

High plasticity

Packaging & Delivery:

1. Delivery: within 7-10 days or considering the quantity;

Transport: By bulk or Containers;

Payment terms L/C, T/T;

2. Packing: It can pack by container or bulk vessel.

Standard export seaworthy package, it use steel belt with bundle according product's size.

We can make it as your requirement.

3003 aluminum coil is the most widely used aluminum alloy. It is made up of aluminum, copper, iron, manganese, silicon, and zinc. It is commonly used because it has great resistance to corrosion and is moderately strong. The 3003 aluminum coil is 20% stronger than 1100 grade alloys because it is fused with manganese. The strength of this alloy can be increased by cold working.

Product Description of The 3003 Aluminium Coil

It is commonly rolled and extruded, but typically not forged. As a wrought alloy, it is not used in casting. The most common applications for the 3003 aluminium coil are for fuel tanks, sheet metal work and other types of projects that need a metal. It is also widely used in sheet metal applications such as HVAC, hinges, condensers, radiators, evaporators, heat shields, gutters, downspouts, and roofing and siding.

Chemical Composition of The 3003 Aluminium Coil

| Elements | Si | Fe | Cu | Mn | Zn | Other | Al |

| Contents | 0.6 | 0.7 | 0.05-0.2 | 1-1.5 | 0.1 | 0.15 | rests |

Specifications of The 3003 Aluminium Coil

| Width (mm) | 40-1600 |

| Roll ID/OD (mm) | Customized |

| Clad material | We supply both aluminum bare material and aluminum clad material, the core material is 3003, and the clad material is 4043 alloy, 10% 4343+3003+10%4343 |

| Typical applications | electronic products aviation meal boxes aluminum honeycomb core |

Advantages of The The 3003 Aluminum Coil

The machinability of the 3003 aluminum is considered good for being an aluminum alloy. It is readily machined for different applications. It can either be formed using conventional hot working or cold working. It’s also possible to use conventional welding methods to shape 3003 aluminum. It is sometimes welded to other aluminium alloys, like 6061, 5052, and 6062, which should have an AL 4043 filler rod.

Aluminum 3003 isn’t heat treatable, but it can be forged with heat that’s between 500 and 950 degrees Fahrenheit. When using heat in this range, the aluminum can be hot worked easily. However, it is readily cold worked, which can be done using conventional methods. When annealing the alloy during or after using cold working techniques, it should be performed at 775 degrees Fahrenheit. This will give it enough time to thoroughly heat before being air-cooled. The only way to make this alloy hard is with the use of cold working. It can also be deep drawn, spun, or brazed.

The 5052 aluminium coil is an alloy made up of 2.5 percent magnesium and 0.25 percent chromium. It’s considered to have great workability and weldability. It has medium static and high fatigue strength. The corrosion resistance of this aluminium is very good, especially in marine environments. This metal has excellent thermal conductivity and low density, like with other aluminium alloys. To harden aluminium 5052, cold working can be used. Heat treatment cannot be used to obtain higher alloy strength.

The fatigue properties of this aluminum are excellent, with a limit of 115 MPa while in the H32 temper and 123 MPa while in H34 temper. Compared to the other aluminum alloys, the 5052 grade of aluminium has midway alloying content and strength. In slightly alkaline environments, 5052 alloys show a resistance level. Its resistance to marine environments is better than that of 5005 alloys, making it a more popular choice for marine applications.

Chemical Composition of 5052 Aluminium Coil

| Elements | Si | Cu | Mg | Zn | Mn | Cr | Fe | Other | Al |

| Contents | 0.25 | 0.1 | 2.2-2.8 | 0.1 | 0.1 | 0.15-0.35 | 0.4 | 0.15 | rests |

Specifications of 5052 Aluminium Coil

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28 |

| Thickness (mm) | 0.014-8 |

| Width (mm) | 40-2600 |

| Length (mm) | Customized |

| Typical applications | Silo, flange material, GIS shellAutomobileBus trunk board marine, petrochemical equipment, and components |

Aluminum sheet plate 5052 is used in many types of industrial applications, including:

Refrigerator liners

Fuel tanks

Storm shutters

Panels

And more

The 5052 aluminum

Performance Advantages

The surface is smooth, no cracks, corrosion spots and traces of nitrate;

High fatigue resistance, good plasticity and corrosion resistance;

Good weldability, poor machinability, polishing;

5052 aluminum coil elongation can reach 12-20%, then the 1060 aluminium plate elongation increased by 200%.

3004 aluminum alloy is an alloy in the wrought aluminum-manganese family (3000 or 3xxx series). It is similar to the 3003 alloys, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminum alloys, heat-treated) to produce tempers with higher strength, but a lower ductility. Like most other aluminum-manganese alloys, 3004 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded (used in the making of beverage cans), but typically not forged. As a wrought alloy, it is not used in casting.

Chemical Composition of 3004 Aluminium Coil

| Elements | Si | Cu | Mg | Zn | Mn | Fe | Al |

| Contents | 0.3 | 0.25 | 0.8-1.3 | 0.25 | 1-1.5 | 0.7 | rests |

Specifications of 3004 Aluminium Coil

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28 |

| Thickness (mm) | 0.014-8 |

| Width (mm) | 40-2600 |

| Roll ID/OD (mm) | Customized |

| Typical applications | AutomobileBus trunk board |

Application of 3004 Aluminium Coil

3004 aluminum coil mainly used for processing the component parts that need to have good formability, high solderability good resistance to corrosion, such as kitchen utensils and appliances, food and chemical products processing and storage devices, transport tank, a tank of liquid products.

3004 aluminum coil mainly used in chemical production and storage equipment, plate processing, building materials, construction, cable pipes, sewer pipes, various parts of lamps and lanterns, cans, wave plate, building materials, color aluminum plate, electric light head.

3004 aluminum sheet mainly used in processing pressure vessel, pipeline, utensil, cooling fin, radiator, makeup board, copy machine roller, ship material.

Specifications of 6061 Aluminium Coil

| Temper | F, O, T4, T6, T651 |

| Thickness (mm) | 0.1-8 |

| Width (mm) | 40-2600 |

| Roll ID/OD (mm) | Customized |

| Typical applications | 3C products automotive wheels trolley case |

Chemical Composition of 6061 Aluminium Coil

| Elements | Cu | Mn | Mg | Zn | Cr | Ti | Si | Fe | Al |

| Contents | 0.14-0.5 | 0.15 | 0.8-1.2 | 0.25 | 0.04-0.35 | 0.15 | 0.4-0.8 | 0.7 | Rests |

Features of 6061 Aluminum Coil

Has excellent electroplating, corrosion resistance and toughness.

High strength, high hardness, no deformation after processing, dense material without defects.

Easy polishing, easy colouring, excellent oxidation effect.

Aluminum is environmentally friendly and can be recycled without pollution.

Performance of 6061 Aluminium Coil

6061 aluminum-magnesium alloy series of high-plastic alloy, heat treatment to strengthen, high impact toughness;

has excellent thermoplastic, welding performance and corrosion resistance;

no deformation after processing, the surface is very smooth, and easy anodizing and colouring;

excellent interface characteristics, high strength, good usability, strong corrosion resistance.

Application of 6061 Aluminium Coil

Construction of aircraft structures, such as wings and fuselages, more commonly in homebuilt aircraft than commercial or military aircraft. 2024 alloy is somewhat stronger, but 6061 is more easily worked and remains resistant to corrosion even when the surface is abraded, which is not the case for 2024, which is usually used with a thin Alclad coating for corrosion resistance.

Yacht construction, including small utility boats.

Automotive parts, such as the chassis of the Audi A8.

Some tactical flashlights.

Aluminium cans for the packaging of food and beverages.

We can manufacture 5083 aluminum plate with many tempers, such as O, H32, H34, H112, H116, H321, etc., and it can be cut to size at customers' need.

| Alloy No. | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| 5083 | 0.4 | 0.4 | 0.1 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.2 | REMAIN | ||

| 5083 Aluminum Alloy Products | ||||||||||||

| Products | Type | Temper | Thickness(mm) | Width(mm) | Length(mm) | |||||||

| 5083 Aluminum Sheet | Mill FinishTread plate | O – H112 | 0.5-350 | 100-2600 | 500-12000 | |||||||

| 5083 Aluminum Coil | 0.5-350 | 100-2600 | Coil | |||||||||

Features and Applications of 5083 Aluminum Coil

5083 aluminum sheet belongs to Al-Mg-Si aluminum alloys. Its main contents are Magnesium and Silicon except Aluminum. Over 4.0% of Magnesium enables 5083 aluminum plate to have excellent resistance to correction, and easily to welded. By adding cooper, 5083 aluminum plate has 28% Electrical conductivity. 5083 aluminum plate also has good forming characteristic for either hot or cold working. But hardening is accomplished by means of cold working only. Besides, 5083 aluminum plate does have good strength but non-heat treatable. 5083 aluminum plate has vast applications for its properties above. It is commonly used in the manufacture of marine, auto aircraft cryogenics, storage tank, railway cars, coachwork, armor plate, building construction, pressure vessels, etc.

5 Series aluminum coil:

The 5 Series aluminum coil is a commonly used industrial material, which is an aluminum-magnesium alloy coil. Its magnesium content is about 3-5%. The main features are: low density, high tensile strength, high extension rate, and high extension rate.

Wide application in conventional industries. The 5 -series aluminum coil currently produced in my country have reached international standards, and technology is relatively mature. It can also be called aluminum -magnesium alloy. The main features are low density, high tensile strength, high extension rate, and good fatigue strength, but not heat treatment enhancement. The weight of aluminum -magnesium alloy in the same area is lower than other series. Application in conventional industries is also wide. The 5000 series aluminum coil in my country are one of the relatively mature aluminum coil series.

CHEMICAL COMPOSITION LIMITS (%)

| Si Silicon | Fe Iron | Cu Copper | Mn Manganese | Mg Magnesium | Cr Chromium | Ni Nickel | Zn Zinc | Ti Titanium | Others Each | Total | Total Aluminum Min |

| 0.25 | 0.4 | 0.1 | 0.1 | 2.2 - 2.8 | 0.15 - 0.35 | - | 0.1 | - | 0.05 | Remainder | 0.15 |

Features of 5 series aluminum coil:

1. Good resistance. 5 Series aluminum coil are the most acid -alkali -resistant corrosion in the 8 aluminum coil series, which allows 5 series aluminum plates to be suitable for the environment that most aluminum plates cannot adapt, which greatly expands the aluminum.

Scope of application.

2. Good processing. The 5 series aluminum coil has high plasticity and has good processing performance, which can adapt to a variety of processing methods such as bending, stamping, and stretching.

3. Good thermal conductivity. The 5 series aluminum coil are excellent thermal conductivity, and are the best materials for making equipment shells and radiator.

4. Strong anti -pressure. The hardness of the 5 series aluminum coil is high in the 8 aluminum coil series, and it can improve the intensity by further processing.

Material

The disadvantages of 5 series aluminum coil:

Although there are many advantages, there are many disadvantages of 5 Series aluminum coil that have not yet been resolved. For example, the 5 Series aluminum coil have poor abrasion resistance, high prices, and poor cutting processing performance. These disadvantages have also increased.

The cost of use of 5 series aluminum coil limits the development of 5 series aluminum coil.

Scope of application:

5052 aluminum coil are commonly used for manufacturing aircraft and car fuel tanks, oil pipes, and sheet metal parts of transportation vehicles and ships. Instrumentation, street light brackets and rivets, hardware products, electrical shells, etc.