Galvanizing is one of the most effective and economical methods for protecting bare steel from corrosive environments. Zinc is not only a barrier between steel and the environment, but also sacrifices itself to protect the steel plate below. When two different metals are in contact and coupled with water and oxygen, sacrifice or current protection occurs. Zinc preferentially corrodes iron in steel. This protection prevents corrosion of the steel in areas not covered by zinc. Therefore, the diffusion of corrosion from cutting edges, drilling holes, etc. is minimized.

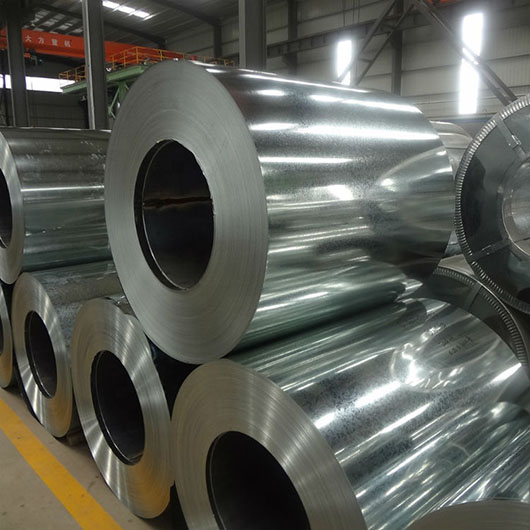

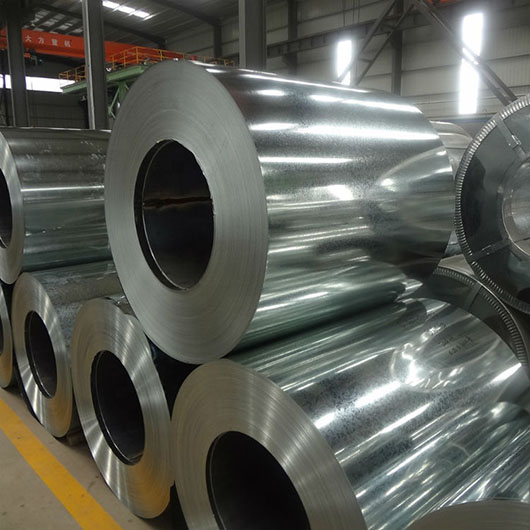

| Product Name | Galvanized Steel Coil |

| Width | 600-1500mm or as customer‘s requirements |

| Thickness | 0.12-3mm,or as customer’s requirements |

| Length | As requirements |

| Zinc coating | 20-275g/m2 |

| Surface | Light Oil, Unoil,dry, chromate passivated, non-chromate passivated |

| Material | DX51D,SGCC,DX52D,ASTMA653,JISG3302, Q235B-Q355B |

| Spangle | Regular spangle, minimal spangle, zero spangle, big spangle |

| Coil Weight | 3-5 Tons or as customer requirements |

| Certifications | ISO 9001 and SGS |

| Packing | Industry standard packaging or according to client’s requirement |

| Delivery time | Up to order quantity,contact us to know |

Hot Dipped Galvanised Steel Coil Surface:

Hot Dipped Galvanised Steel Coil will have different surface states because of different treatment during the coating process. Such as regular galvanized steel coil, thin galvanized steel coil, smooth galvanized steel coil, zero galvanized steel coil and phosphating surface.

Hot Dipped Galvanised Steel Coil Characteristics:

1.Strong corrosion resistance

2.High surface quality

3.Conducive to deep processing,such as corrugated steel sheet

4. Economy and practicality

Application:

Galvanised steel coils are widely used in the following industries:

In the construction industry: to manufacture structural elements low-rise construction, light steel thin-walled structures, sandwich panels, lining of heat pipelines and various heat insulation, conditioning systems, metal roof shingle, profiled sheeting, culvert pipes, cladding of entry doors, elevators, reinforcement profiles for PVC windows and plastic doors, European-type fasteners for plasterboards, etc

In the automotive industry: to manufacture external and internal car body parts, as well as to repair external public transport body parts, eg for buses and trams)

In the machine building and instrumentation industries: to manufacture cases for electrical and mechanical equipment, home appliances, metering devices and packing

To manufacture houseware (tableware, bowls, buckets, tanks, baths, etc)

To manufacture colour-coated (and other type of coating) rolled steel